Bicheng Electronics Technology Co., Ltd

Company Profile

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in

Shenzhen China, severing cellular base station antenna, satellite,

high frequency passive components, microstrip line and band line

circuit, millimeter wave equipment, radar systems, digital radio

frequency antenna and other fields worldwide for 18 years. Our high

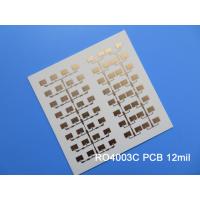

frequency PCBs are mainly built on 3 high frequency material

brands: Rogers Corporation, Taconic and Wangling. Dielectric

constant ranges from 2.2 to 10.2 etc.

Bicheng PCB is headquartered in Shenzhen, a city with great

economic vitality. Based in China, we adhere to the philosophy of

servicing small and medium sized companies offering variety of

circuit boards to meet the demands of market.

Main Business & PCB Applications

We maintain the highest standards which support products that

exhibit exceptional quality, performance and reliability. We also have divisions of FR-4 circuit board, flexible circuits

and metal core PCBs featured as prototypes, small runs to mass

production. We actively research and build such high value

added PCB projects as HDI, quick turn, impedance control, heavy

copper and backplane board etc. This has made our PCB products

generate an effective prolongation and complementation, as well as

formation of integrated products line ranging from low-end to

high-end.The circuit boards are used in the industries of home

appliances, portable and consumable electronics, medical filed,

aerospace as well as telecommunications etc.

Main Material Partners