Hua Dong Boiler Co., Ltd. is a high-tech enterprise specialized in

manufacturing boilers. Established in early 1985s, has two

manufacturing bases, this company covers 400,000㎡ with fixed assets

amounting to USD 110,000,000. There are 1100 employees including

150 technicians and 600 coded welders. Hua Dong holds the

manufacturing licenses for Grade A boilers and Grade A1&A2

pressure vessels issued by Chinese General Administration of

Quality Supervision, Inspection and Quarantine; also it holds the

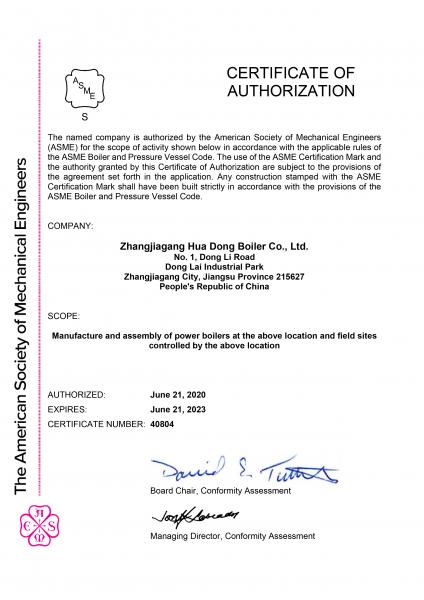

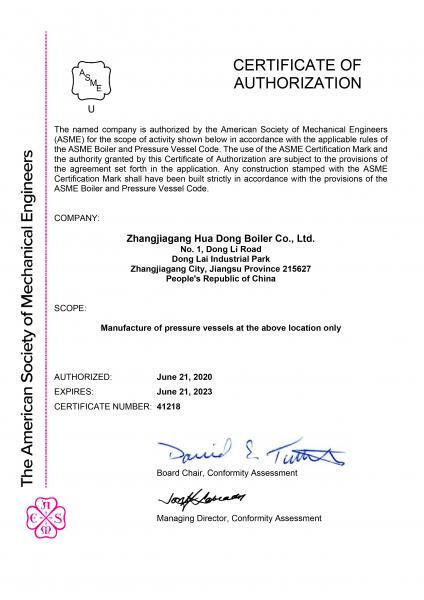

"S" and "U" "NB" stamps issued by American Society of Mechanical

Engineers; meanwhile, this Company has passed the certification of

ISO9001, SO3834, EN12952 Quality Management System.

"Hua Dong" boilers include Utility Boiler, HRSG Boiler, coal-fired

, oil(gas) -fired, coal-water-slurry-fired and garbage-fired

steam/hot water boilers, organic heat carrier boilers, etc., and

Boiler spare parts (Economizer, Finned tube, Header, Steam drum,

Superheater, Water wall panel, Air preheater, Cyclone separator,

etc., which are widely used in power generation, heat supply,

chemical engineering, textile, food, paper, road building, plastic,

rubber and wood working industries. "HD" boilers are honored as

"Famous Production in Jiangsu Province", " Jiangsu High-Tech

Product" and "Jiangsu Energy-Saving Product". "HD" brand is a

"Famous Brand in Jiangsu Province". We are a qualified supplier for

the top three boiler manufacturers in China(Harbin Boiler Co.,

Ltd., Dong Fang Boiler Group Co., Ltd., Shanghai Boiler Works

Ltd.,). So far, Hua Dong Boilers have served 10000 customers, which

sell well all over China and are exported to USA, Australia,

Russia, Kazakhstan, India, Indonesia, South Africa, Brazil, and

Southeast Asia.

We strive to manufacture "Safe, Efficient, Energy-Saving and

Environment-Friendly" boilers, provide new-type products in

excellent quality, serve users sincerely to their satisfaction, and

be a top supplier of boilers in China.

Declaration

Zhangjiagang Hua Dong Boiler Co.,Ltd has no subsidiaries.

Packaging & Shipping

Company Business

Our products have been wildly used in power plants and large

international companies overseas.