Product Description:

The Industrial PPS Material Board, commonly known as the

Polyphenylene Sulfide Board, is an advanced engineering

thermoplastic product designed for demanding industrial

applications. Known for its outstanding mechanical and chemical

properties, this board is an essential material for industries that

require high-performance, reliable, and durable components. The

Industrial PPS Material Board is manufactured with a smooth surface

finish, ensuring excellent machinability and an aesthetically

pleasing appearance for various applications.

One of the key characteristics of this Polyphenylene Sulfide Board

is its superior thermal stability. With a melting point ranging

between 280 to 285 °C, this board can withstand high-temperature

environments without compromising its structural integrity. This

makes the Industrial PPS Material Board an ideal choice for

components exposed to continuous heat or thermal cycling in

industrial settings. Its ability to maintain performance at

elevated temperatures ensures longevity and reduces the need for

frequent replacements.

The Industrial PPS Material Board also boasts an impressive

flammability rating of UL94 V-0, which means it is highly flame

retardant. This rating is critical for applications where fire

safety is paramount, providing peace of mind to manufacturers and

end-users alike. The UL94 V-0 rating ensures that the material

stops burning within 10 seconds on a vertical specimen and does not

drip flaming particles, making it an excellent choice for

electrical, automotive, and aerospace industries where stringent

safety standards must be met.

In terms of physical appearance, the Polyphenylene Sulfide Board

comes in a natural color, often described as beige or light brown.

This neutral color not only adds to the board’s versatility but

also allows for easy customization through painting or coating if

required. The natural color also signifies the purity and high

quality of the material used in the manufacturing process, ensuring

consistent performance across different batches.

The thickness of the Industrial PPS Material Board ranges from 3mm

to 30mm, offering flexibility to meet various design and

application requirements. Whether thin sheets are needed for

lightweight components or thicker boards are required for

structural parts, this range allows engineers and designers to

select the perfect thickness for their specific needs. The

availability of multiple thickness options enhances the board’s

adaptability across diverse industrial sectors.

Manufactured with precision and stringent quality control, the

Industrial PPS Material Board provides excellent mechanical

strength, chemical resistance, and dimensional stability. It is

resistant to a wide range of chemicals, including acids, bases, and

solvents, making it suitable for harsh environments such as

chemical processing plants and manufacturing facilities.

Additionally, the board’s excellent wear resistance and low

friction properties contribute to its long service life in

applications involving sliding or moving parts.

In summary, the Industrial PPS Material Board is a high-performance

Polyphenylene Sulfide Board that combines a smooth surface finish,

high melting point, excellent flame retardancy, natural coloration,

and a versatile thickness range. These attributes make it a

preferred material for industries requiring reliable, durable, and

safe components capable of withstanding challenging operating

conditions. Whether used in electrical insulation, automotive

parts, aerospace components, or chemical processing equipment, the

Industrial PPS Material Board delivers consistent quality and

superior performance, making it an indispensable material in modern

industrial manufacturing.

Features:

- Product Name: Polyphenylene Sulfide Board (PPS Board)

- Flammability Rating: UL94 V-0 for enhanced fire safety

- Water Absorption: Less than 0.1%, ensuring excellent moisture

resistance

- Flexural Strength: Ranges between 120 - 150 MPa for superior

mechanical performance

- Size: Customized to meet specific application requirements

- Heat Deflection Temperature: Between 260 - 280 °C, suitable for

high-temperature environments

- Chemical Resistant PPS Board, providing durability in harsh

chemical conditions

Technical Parameters:

| Material | Polyphenylene Sulfide (PPS) |

| Density | 1.35 - 1.38 G/cm³ |

| Thickness | 3-30 mm |

| Color | Natural (Beige/Light Brown) |

| Heat Deflection Temperature | 260 - 280 °C |

| Flexural Strength | 120 - 150 MPa |

| Weather Resistance | Good |

| Flammability Rating | UL94 V-0 |

| Melting Point | 280 - 285 °C |

| Applications | Electrical Components, Automotive Parts, Industrial Machinery |

Applications:

The Engineering PPS Plastic Board is a highly versatile material

widely used in various demanding applications due to its

exceptional thermal stability, mechanical strength, and chemical

resistance. With a melting point ranging from 280 to 285 °C and a

density between 1.35 and 1.38 g/cm³, the Polyphenylene Sulfide

Board is ideally suited for environments that require reliable

performance under high temperatures and mechanical stress. Its

natural beige or light brown color and very low water absorption

rate of less than 0.1% further enhance its suitability for

precision and durability-focused applications.

One of the primary application occasions for the Engineering PPS

Plastic Board is in electrical components. Thanks to its excellent

electrical insulation properties and dimensional stability, this

PPS board is commonly used in manufacturing insulators, connectors,

and various other electrical parts that must endure high heat and

resist moisture. Its low water absorption ensures that the

electrical components maintain their integrity and performance even

in humid or damp conditions, making it an excellent choice for use

in household appliances and industrial electrical systems.

In the automotive industry, the Engineering PPS Plastic Board plays

a crucial role in the production of automotive parts. Its high

melting point and mechanical robustness enable it to withstand the

demanding thermal and mechanical stresses encountered in engine

compartments and other high-temperature zones. Polyphenylene

Sulfide Board is often utilized to fabricate parts such as fuel

system components, under-the-hood brackets, and connectors, where

both chemical resistance and dimensional stability are essential.

Its natural color also facilitates easy identification and quality

control during manufacturing processes.

Industrial machinery applications benefit significantly from the

properties of the Engineering PPS Plastic Board. The material’s

resistance to wear, chemicals, and high temperatures makes it ideal

for use in gears, bushings, and pump components that operate under

continuous stress and harsh conditions. The low water absorption

characteristic ensures that the board maintains its mechanical

properties even when exposed to moisture or lubricants, thereby

enhancing the longevity and reliability of machinery parts.

Overall, the Engineering PPS Plastic Board is a premium choice for

applications requiring high thermal resistance, mechanical

strength, and chemical durability. Whether it is used in electrical

components, automotive parts, or industrial machinery, the

Polyphenylene Sulfide Board consistently delivers superior

performance, making it indispensable in modern engineering and

manufacturing industries.

Customization:

Our PPS Board offers versatile product customization services to

meet your specific industrial needs. Manufactured using advanced

methods such as Injection Molding, Extrusion, and Machining, this

Chemical Resistant PPS Board ensures high precision and durability.

Made from premium Polyphenylene Sulfide (PPS), the Engineering PPS

Plastic Board boasts an impressive heat deflection temperature

range of 260 - 280 °C, making it suitable for high-temperature

applications. Additionally, it meets the stringent UL94 V-0

flammability rating, ensuring superior fire resistance and safety.

Whether you require tailored dimensions, shapes, or machining

specifications, our Industrial PPS Material Board customization

services provide flexible solutions to enhance performance and meet

your exact requirements.

Support and Services:

Product Technical Support and Services for the PPS Board are

designed to ensure optimal performance and user satisfaction. Our

dedicated support team provides comprehensive assistance, including

installation guidance, troubleshooting, firmware updates, and

maintenance tips.

We offer detailed product documentation and user manuals to help

you get started quickly and utilize all features effectively.

Regular software and firmware updates are available to enhance

functionality and security.

In case of technical issues, our support specialists are available

to diagnose problems and provide timely solutions. We also offer

repair services and replacement parts to maintain the longevity of

your PPS Board.

For customized solutions and integration support, our experts can

assist in tailoring the PPS Board to meet specific application

requirements. We are committed to delivering high-quality support

to maximize your investment and ensure seamless operation.

Packing and Shipping:

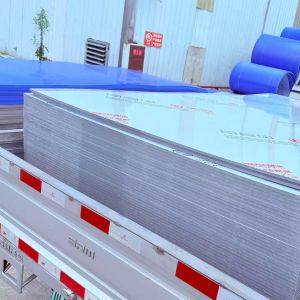

Our PPS Board products are carefully packaged to ensure maximum

protection during transit. Each board is wrapped with protective

film and placed between sturdy cardboard sheets to prevent

scratches and damage. The packaged boards are then securely sealed

in heavy-duty cartons designed to withstand handling and shipping

conditions.

For shipping, we use reliable logistics partners to guarantee

timely delivery. Each shipment is accompanied by detailed

documentation, including packing lists and product specifications.

We offer various shipping options to meet customer needs, including

express, standard, and bulk freight services. Tracking information

is provided once the order is dispatched to keep customers informed

throughout the delivery process.

FAQ:

Q1: What is PPS Board made of?

A1: PPS Board is made from Polyphenylene Sulfide, a

high-performance thermoplastic known for its excellent chemical

resistance, thermal stability, and mechanical strength.

Q2: What are the typical applications of PPS Board?

A2: PPS Boards are commonly used in electrical insulation,

automotive components, chemical processing equipment, and

mechanical parts that require high durability and heat resistance.

Q3: What temperature range can PPS Board withstand?

A3: PPS Board can typically withstand continuous operating

temperatures up to 260°C (500°F), making it suitable for

high-temperature applications.

Q4: Is PPS Board resistant to chemicals?

A4: Yes, PPS Board has excellent resistance to a wide range of

chemicals, including acids, bases, and organic solvents, which

makes it ideal for harsh chemical environments.

Q5: Can PPS Board be machined or fabricated easily?

A5: PPS Board can be machined, cut, drilled, and fabricated using

standard tools, allowing for custom shapes and sizes to meet

specific application requirements.