Product Description:

The High Performance PPS Board is an advanced engineering material

designed to meet the rigorous demands of various industrial

applications. With a thickness range from 3mm to 30mm, this board

offers versatility and adaptability, making it suitable for a wide

array of uses where precision and durability are paramount. Its

robust construction ensures that it can be customized to fit

specific requirements, whether for thin, lightweight components or

thicker, more structural elements.

One of the standout features of this Chemical Resistant PPS Board

is its exceptional chemical resistance. PPS (Polyphenylene Sulfide)

is renowned for its ability to withstand exposure to harsh

chemicals, acids, and solvents without degrading, making this board

an ideal choice for environments where chemical exposure is a

concern. This chemical resistance ensures long-lasting performance

and reliability, reducing maintenance costs and downtime caused by

material failure due to chemical attack.

In addition to its chemical resistance, the High Performance PPS

Board boasts a flammability rating of UL94 V-0. This rating

signifies that the material is self-extinguishing and does not

propagate flames, which is crucial for applications requiring

stringent fire safety standards. The UL94 V-0 rating offers peace

of mind for manufacturers and end-users, ensuring that the board

contributes to safer working environments and complies with

industry regulations regarding fire safety.

Mechanical strength is another critical attribute of this Chemical

Resistant PPS Board. It exhibits an impressive flexural strength

ranging from 120 to 150 MPa, demonstrating its capability to

withstand significant bending forces without breaking or deforming.

This strength makes it suitable for load-bearing applications and

structural components that must endure mechanical stress while

maintaining dimensional stability and integrity over time.

The surface finish of the High Performance PPS Board is smooth,

providing an excellent aesthetic and functional quality. A smooth

surface finish not only enhances the visual appeal but also

facilitates easier cleaning and maintenance. This feature is

particularly beneficial in applications where hygiene and

cleanliness are vital, such as in medical, food processing, or

laboratory environments. Moreover, the smooth surface aids in

reducing friction and wear when the board is used in moving or

contact applications.

Thermal performance is a critical consideration for many industrial

materials, and the Chemical Resistant PPS Board excels in this

regard with a heat deflection temperature between 260 and 280 °C.

This high heat deflection temperature means the board can withstand

elevated temperatures without deforming or losing its mechanical

properties. It is well-suited for applications involving continuous

exposure to heat or thermal cycling, such as in automotive,

electrical, and aerospace industries where reliable performance

under thermal stress is essential.

Overall, the High Performance PPS Board combines chemical

resistance, mechanical strength, fire safety, and thermal stability

in a versatile and reliable engineering material. Its range of

thicknesses from 3mm to 30mm, coupled with its smooth surface

finish, makes it adaptable to a variety of applications, from

precision components to structural parts. Whether used in harsh

chemical environments, high-temperature settings, or situations

demanding stringent fire resistance, this Chemical Resistant PPS

Board delivers superior performance and longevity.

In summary, the High Performance PPS Board is an exceptional choice

for industries seeking a durable, chemical resistant PPS board with

excellent mechanical properties and thermal stability. Its UL94 V-0

flammability rating, high flexural strength of 120-150 MPa, and

ability to maintain integrity at temperatures up to 280 °C position

it as a leading material in advanced engineering applications. The

smooth surface finish further enhances its usability, making it a

preferred solution for manufacturers looking to optimize

performance, safety, and durability in their products.

Features:

- Product Name: PPS Board

- Material: Engineering PPS Plastic Board (Polyphenylene Sulfide

Board)

- Flammability Rating: UL94 V-0

- Color: Natural (Beige/Light Brown)

- Weather Resistance: Good

- Applications: Electrical Components, Automotive Parts, Industrial

Machinery

- High-performance Engineering PPS Plastic Board suitable for

demanding environments

Technical Parameters:

| Product Name | PPS Board |

| Surface Finish | Smooth |

| Weather Resistance | Good |

| Color | Natural (Beige/Light Brown) |

| Heat Deflection Temperature | 260 - 280 °C |

| Manufacturing Methods | Injection Molding, Extrusion, Machining |

| Water Absorption | < 0.1% |

| Flexural Strength | 120 - 150 MPa |

| Melting Point | 280 - 285 °C |

| Density | 1.35 - 1.38 G/cm³ |

Applications:

The Polyphenylene Sulfide Board, commonly known as PPS Board, is a

highly versatile engineering material prized for its exceptional

properties such as heat resistance, chemical resistance, and

mechanical strength. Its smooth surface finish and customizable

size options, with thickness ranging from 3 to 30mm, make it an

ideal choice for a wide array of applications across various

industries. The natural beige or light brown color of the board

adds to its aesthetic appeal while maintaining its functional

excellence.

One of the primary application occasions for the Heat Resistant PPS

Board is in environments where high temperatures are prevalent. Due

to its excellent thermal stability and ability to maintain

mechanical integrity at elevated temperatures, it is widely used in

the manufacturing of components for automotive engines, electrical

insulation parts, and heating elements. Industries involved in

electronics and electrical engineering benefit greatly from the PPS

Board’s capacity to withstand heat without deformation or loss of

performance.

The Chemical Resistant PPS Board finds extensive use in chemical

processing plants, laboratories, and pharmaceutical manufacturing

facilities. Its high density, ranging between 1.35 and 1.38 g/cm³,

contributes to its durability and resistance against a wide variety

of chemicals, including acids, alkalis, and solvents. This makes it

suitable for fabricating tanks, pipes, and protective linings that

require long-term exposure to aggressive chemical environments.

In addition to industrial uses, the Polyphenylene Sulfide Board is

also employed in precision machining and fabrication due to its

smooth surface finish and customizable thickness. This allows for

the creation of bespoke components such as gears, bearings, and

seals that demand tight tolerances and high performance under

mechanical stress. The board’s natural color and texture also make

it suitable for prototype development and design applications where

visual inspection is important.

Overall, the PPS Board serves as an excellent material choice for

any scenario requiring a combination of heat resistance, chemical

resistance, and mechanical robustness. Its adaptability in size and

thickness enables engineers and designers to tailor solutions that

meet specific operational demands, ensuring reliability and

longevity in challenging conditions.

Customization:

Our Industrial PPS Material Board offers comprehensive product

customization services to meet your specific requirements. We

provide Polyphenylene Sulfide Board in customized sizes to

perfectly fit your project needs. This Chemical Resistant PPS Board

is ideal for applications in electrical components, automotive

parts, and industrial machinery, ensuring high performance and

durability.

The board features a density range of 1.35 - 1.38 G/cm³, providing

excellent mechanical strength and stability. With a smooth surface

finish, it is suitable for precision manufacturing and aesthetic

applications. Additionally, the material boasts a high melting

point of 280 - 285 °C, making it resistant to extreme temperatures

and ideal for demanding industrial environments.

Choose our customized Industrial PPS Material Board for reliable,

high-quality Polyphenylene Sulfide Board solutions that cater to

your unique industry needs.

Support and Services:

Product Technical Support and Services for the PPS Board are

designed to ensure optimal performance and reliability. Our support

team provides comprehensive assistance including installation

guidance, troubleshooting, firmware updates, and maintenance tips.

We offer detailed documentation and user manuals to help you

understand the features and functionalities of the PPS Board. In

case of technical issues, our experts are ready to assist with

diagnostics and problem resolution to minimize downtime.

Regular software updates and patches are provided to enhance

security and add new capabilities. Additionally, we provide

training sessions and webinars to help users maximize the use of

their PPS Board.

For warranty services, repairs, and replacement parts, we ensure

timely and efficient processing to maintain the continuous

operation of your systems.

Our goal is to deliver exceptional customer service and technical

expertise to support your success with the PPS Board product.

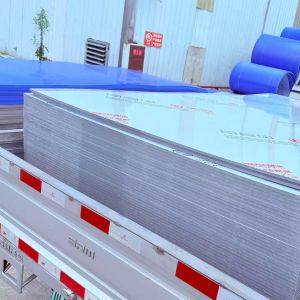

Packing and Shipping:

Our PPS Board product is carefully packaged to ensure maximum

protection during transit. Each board is wrapped in a protective

film to prevent scratches and then securely placed in a sturdy

cardboard box. The packaging is designed to withstand handling and

environmental factors, ensuring the product arrives in perfect

condition.

For shipping, we use reliable courier services with tracking

options available. Orders are processed promptly and dispatched

within 2-3 business days. We offer various shipping methods to

accommodate your delivery needs, including standard and expedited

options. International shipping is also available with appropriate

customs documentation.

Please ensure the delivery address is accurate to avoid any delays.

In case of any damage during shipping, contact our customer service

immediately for assistance.

FAQ:

Q: What is the PPS Board made of?

A: The PPS Board is made from high-quality polyphenylene sulfide

(PPS), a durable thermoplastic known for its excellent chemical

resistance and thermal stability.

Q: What are the typical applications of the PPS Board?

A: PPS Boards are commonly used in electrical insulation,

automotive parts, chemical processing equipment, and other

industrial applications requiring high mechanical strength and heat

resistance.

Q: What temperature range can the PPS Board withstand?

A: PPS Boards can typically withstand continuous operating

temperatures up to 260°C (500°F), making them suitable for

high-temperature environments.

Q: Is the PPS Board resistant to chemicals?

A: Yes, the PPS Board has excellent chemical resistance and can

withstand exposure to acids, bases, solvents, and other harsh

chemicals without degradation.

Q: Can the PPS Board be machined or fabricated?

A: Yes, PPS Boards can be easily machined, drilled, and fabricated

using standard tools, allowing for custom shapes and sizes to fit

specific needs.