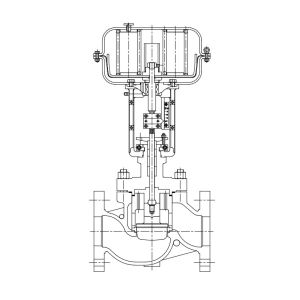

FR Series Pneumatic Eccentric Control Valve

The FR series pneumatic eccentric rotary control valve (also known as the cam flexure valve) adopts Masoneilan technology combined with China's characteristics. It integrates the advantages of single-seat valves, ball valves, butterfly valves, etc., and has prominent features such as a simple structure, small size, light weight, large rated flow coefficient, wide adjustable range, wide operating temperature range, small leakage, and good stability.

Since the valve core and valve stem only perform rotational movement, the friction force they bear during operation is very small. When the valve core and valve seat are in contact and closed, the flexible arm of the valve core produces slight elastic deformation and elastic tension under the thrust of the actuator, making the contact between the valve core and the valve seat more tight and firm. Therefore, the leakage of the eccentric valve is very small. At the same time, the actuator thrust required to close the valve is smaller compared with ball valves and butterfly valves.

For these reasons, this series of products is widely used in industrial process automatic control systems such as chemical industry, metallurgy, and power plants.

| Structural Materials |

| Serial Number | Name | Material |

| 1 | Valve Body | WCB SCS13 SCS14 ZG25 ZGICr18Ni9 ZG0Cr18Ni12Mo2Ti |

| 2 | Lower Guide Bushing | 9Cr18 SUS316+ST |

| 3 | Valve Seat | 0Cr18Ni12Mo2Ti SUS316+ST |

| 4 | Valve Core | SUS316+ST |

| 5 | Gland Nut | 0Cr18Ni12Mo2Ti SUS316+ST |

| 6 | Upper Guide Bushing | 9Cr18 SUS316+ST |

| 7 | Valve Stem | 0Cr18Ni12Mo2Ti SUS316 |

| 8 | Gasket | 1Cr18Ni90Cr18Ni12Mo2Ti |

| 9 | Packing | Polytetrafluoroethylene (PTFE) + Asbestos, Graphite |

| 10 | Packing Bolt | 1Cr18Ni9 |

| 11 | Packing Gland | 1Cr18Ni9 |

| 12 | Pressure Plate | ZG25 ZG1Cr18Ni9 |

| 13 | Nut | 1Cr18Ni9 |

| 1. Basic technical parameters |

| Caliber | 1" | 1"

12 | 2" | 3" | 4" | 6" | 8" | 10" | 12" |

| Flow coefficient Cv | 14 | 30 | 50 | 135 | 230 | 500 | 850 | 1300 | 1750 |

| 8.4 | 18 | 30 | 81 | 138 | 300 | 510 | 780 | 1050 |

| 5.6 | 12 | 20 | 54 | 92 | 200 | 340 | 520 | 700 |

| Flow characteristic | Approximate value line (logarithmic linear and other characteristics must be equipped with a valve positioner) |

| Pressure class | ANSI150300600 |

| Stroke | Rotation angle 50° |

| Valve seat leakage | ANSI B16.104 Ⅳ (metal seal) Ⅵ (soft seal) |

| Operating temperature (℃) | -195~+400 |

| Turndown ratio | 100∶1 |

| Actuator | Rolling diaphragm type | DL1 | DL2 | DL3 |

| Pneumatic piston type | PL1 | PL2 | PL3 | PL4 |

| Connection form | Wafer type |

| 3. Structural materials |

| Serial Number | Name | Material |

| 1 | Valve Body | WCBSCS13SCS14ZG25ZGlCr18Ni9ZG0Cr18Ni12Mo2Ti |

| 2 | Lower Guide Bushing | 9Cr18SUS316+ST |

| 3 | Valve Seat | 0Cr18Ni12Mo2TiSUS316+ST |

| 4 | Valve Core | SUS316+ST |

| 5 | Gland Nut | 0Cr18Ni12Mo2TiSUS316+ST |

| 6 | Upper Guide Bushing | 9Cr18SUS316+ST |

| 7 | Valve Stem | 0Cr18Ni12Mo2TiSUS316 |

| 8 | Gasket | 1Cr18Ni90Cr18Ni12Mo2Ti |

| 9 | Packing | Polytetrafluoroethylene + asbestos graphite |

| 10 | Packing bolt | 1Cr18Ni9 |

| 11 | Packing gland | 1Cr18Ni9 |

| 12 | Pressure plate | ZG25ZG1Cr18Ni9 |

| 13 | Nut | 1Cr18Ni9 |

4. Allowable pressure difference

| (1) Hard seal structure Unit: MPa |

| Caliber | Cv | Air-to-open and flow-opening type | Air-to-open and flow-closing type or air-to-close and flow-opening type |

| Air supply pressure |

| 0.14 | 0.18 | 0.21 | 0.25 | 0.28 | 0.32 | 0.35 | 0.39 | 0.42 | 0.46 | 0.49 | 0.53 |

| 1" | 14

5.6 | 7.0

10.2 | 7.0

10.0 | | | | | | | | | | | |

"

1

1

2 | 30

12 | 4.7

9.8 | 3.0

6.3 | 5.6

10.2 | | | | | | | | | | |

| 2" | 50

20 | 2.5

5.2 | 1.6

3.3 | 3.5

7.0 | 4.2

7.0 | | | | | | | | | |

| 3" | 135

54 | 2.0

4.5 | 1.3

2.8 | 2.7

6.1 | 4.2

7.0 | | | | | | | | | |

| 4" | 230

92 | 1.0

2.2 | 0.63

1.4 | 1.4

3.0 | 2.2

4.9 | 3.1

6.8 | 3.9

7.0 | 4.1

7.0 | | | | | | |

| 6" | 500 | 0.63 | | | 0.35

0.35

0.35 | 0.91

0.91

0.91 | 1.4

1.4

1.4 | 2.1

2.1

2.1 | 2.5

2.5 | 3.1

3.1 | 3.7

3.7 | 4.2

4.2 | | |

| 200 | 1.4 | | | 0.77

0.77

0.77 | 2.0

2.0

2.0 | 3.2

3.2

3.2 | 4.4

4.4

3.5 | 5.6

5.6 | 6.8

6.8 | 7.0

7.0 | | | |

| | 850 | 0.32 | | | 0.18

0.18

0.18 | 0.42

0.42

0.42 | 0.7

0.7

0.63 | 1.0

1.0 | 1.3

1.3 | 1.5 | 1.8 | 2.1 | 2.4 | 2.5 |

| 8" | 510 | 0.49 | | | 0.28

0.28

0.28 | 0.7

0.7

0.7 | 1.1

1.1

1.0 | 1.5

1.5 | 2.0

2.0 | 2.4 | 2.8 | 3.2 | 3.7 | 3.9 |

| | 340 | 0.77 | | | 0.42

0.42

0.42 | 1.1

1.1

1.0 | 1.8

1.8

1.5 | 2.5

2.5 | 3.2

3.2 | 3.9 | 4.5 | 5.2 | 5.9 | 6.3 |

| 10" | 1300 | 0.18 | | | 0.11

0.11

0.11 | 0.25

0.25

0.25 | 0.38

0.35

0.38 | 0.56

0.56 | 0.7

0.7 | 0.84 | 0.98 | 1.1 | 1.3 | 1.5 |

| 780 | 0.42 | | | 0.14

0.14

0.14 | 0.35

0.35

0.35 | 0.56

0.56

0.49 | 0.84

0.84 | 1.1

1.1 | 1.3 | 1.5 | 1.8 | 2 | 2.2 |

| 520 | 0.42 | | | 0.25

0.25

0.25 | 0.63

0.63

0.63 | 0.98

0.98

0.84 | 1.3

1.3 | 1.7

1.7 | 2.1 | 2.5 | 2.8 | 3.2 | 3.6 |

| | 1750 | 0.11 | | | | 0.14

0.14

0.14 | 0.21

0.21

0.621 | 0.32

0.32 | 0.39

0.39 | 0.49

0.42 | 0.56 | 0.63 | 0.7 | 0.84 |

| 12" | 1050 | 0.14 | | | 0.07

0.07

0.07 | 0.21

0.21

0.21 | 0.35

0.35

0.32 | 0.49

0.49 | 0.63

0.63 | 0.7 | 0.84 | 0.98 | 1.1 | 1.3 |

| | 700 | 0.25 | | | 0.14

0.14

0.14 | 0.35

0.35

0.35 | 0.56

0.56

0.49 | 0.77

0.77 | 0.98

0.98 | 1.3 | 1.5 | 1.7 | 1.9 | 2.1 |

| (2) Soft seal structure Unit: MPa |

| Caliber | Cv | Air-to-open and flow-opening type | Air-to-open and flow-closing type or air-to-close and flow-opening type |

| Air supply pressure |

| 0.14 | 0.18 | 0.21 | 0.25 | 0.28 | 0.32 | 0.35 | 0.39 | 0.42 | 0.46 | 0.49 | 0.53 |

| 1" | 14

5.6 | 5.6

7.0 | 5.6

7.0 | | | | | | | | | | | |

"

1

1

2 | 30

12 | 3.5

7.0 | 1.6

3.7 | 4.9

7.0 | | | | | | | | | | |

| 2" | 50

20 | 1.8

3.7 | 0.7

1.6 | 2.6

5.3 | 4.2

7.0 | | | | | | | | | |

| 3" | 135

54 | 1.4

3.4 | 0.62

1.6 | 2.1

4.8 | 3.5

5.6 | | | | | | | | | |

| 4" | 230

92 | 0.7

1.6 | 0.25

0.7 | 1.1

2.3 | 1.8

4.0 | 2.6

5.6 | 3.4

5.6 | 3.5

5.6 | | | | | | |

| 6" | 500 | 0.42 | | | 0.14

0.14

0.14 | 0.63

0.63

0.63 | 1.2

1.2

1.2 | 1.7

1.7

1.7 | 2.2

2.2

2.5 | 2.7

2.7 | 3.2

3.2 | 3.5

3.5 | | |

| 200 | 1.1 | | | 0.42

0.42

0.42 | 1.5

1.5

1.5 | 2.7

2.7

2.7 | 3.7

3.7

3.7 | 4.8

4.8 | 5.6

5.6 | | | | |

| | 850 | 0.14 | | | | 0.28

0.28

0.28 | 0.52

0.52

0.52 | 0.77

0.77

0.63 | 1.1

1.1 | 1.3

1.3 | 1.5 | 1.8 | 2.1 | |

| 8" | 510 | 0.28 | | | 0.07

0.07

0.07 | 0.46

0.46

0.46 | 0.84

0.84

0.84 | 1.2

1.2

0.96 | 1.6

1.6 | 2.0

2.0 | 2.4 | 2.8 | 3.2 | |

| | 340 | 0.49 | | | 0.14

0.14

0.14 | 0.77

0.77

0.77 | 1.4

1.4

1.4 | 2.0

2.0

1.5 | 2.6

2.6 | 3.2

3.2 | 3.8 | 4.4 | 4.9 | |

| 10" | 1300 | | | | | 0.11

0.11

0.11 | 0.25

0.25

0.25 | 0.38

0.38

0.35 | 0.53

0.53 | 0.67

0.67 | 0.77

0.70 | 0.91 | 1.1 | 1.2 |

| 780 | 1.1 | | | | 0.21

0.21

0.21 | 0.42

0.42

0.42 | 0.63

0.63

0.63 | 0.84

0.84 | 1.1

1.1 | 1.3 | 1.5 | 1.7 | 1.9 |

| 520 | 0.21 | | | | 0.35

0.35

0.35 | 0.7

0.7

0.7 | 1.1

1.1

0.84 | 1.3

1.3 | 1.7

1.7 | 2 | 2.3 | 2.7 | 3 |

| | 1750 | | | | | 0.04

0.04

0.04 | 0.11

0.11

0.11 | 0.18

0.18

0.18 | 0.28

0.28

0.21 | 0.35

0.35 | 0.42

0.42 | 0.49 | 0.6 | 0.67 |

| 12" | 1050 | | | | | 0.07

0.07

0.07 | 0.21

0.21

0.21 | 0.32

0.32

0.32 | 0.46

0.46 | 0.56

0.56 | 0.7 | 0.77 | 0.91 | 1.1 |

| | 700 | 0.07 | | | | 0.18

0.18

0.18 | 0.35

0.35

0.35 | 0.56

0.56

0.56 | 0.77

0.77 | 0.91

0.91 | 1.1

0.90 | 1.3 | 1.5 | 1.8 |

| Note: - If the allowable pressure difference exceeds the value in the table, it is recommended to use a piston-type actuator.

- If the Cv value is greater than 500, it is recommended to use a piston-type actuator.

- The allowable pressure difference shall not exceed the nominal pressure of the valve.

|

Accessories

Since the flow characteristic of the FR series pneumatic eccentric rotary control valve is approximately linear, a valve positioner (including an air filter pressure reducer) must be equipped in occasions where control accuracy is required. In addition, auxiliary components such as electro-pneumatic converters, position retaining valves, safety valves, travel switches, and solenoid valves can also be equipped according to process requirements.

The handwheel of the FR series is integrated with the valve, and it can be supplied without special indication when the user places an order.

External dimensions and weight

| Equipped with a rolling diaphragm actuator Unit: mm |

| DN | A | B | C | D | E | F | G | H | J | K | L | weight

(Kg) |

| Flangeless | Flangeless |

| 1" | 102 | 173 | 297 | 208 | 163 | 140 | 110 | 67 | 206 | 38 | 137 | 12 |

| ” | 114 | 175 | 300 | 211 | 163 | 140 | 110 | 62 | 234 | 51 | 165 | 14 |

| 2" | 124 | 175 | 300 | 211 | 163 | 140 | 110 | 62 | 239 | 66 | 170 | 16 |

| 3" | 165 | 262 | 434 | 229 | 163 | 175 | 118 | 97 | 333 | 84 | 244 | 35 |

| 4" | 194 | 264 | 437 | 229 | 163 | 175 | 118 | 106.5 | 356 | 109 | 267 | 48 |

| 6" | 229 | 330 | 533 | 302 | 254 | 218 | 197 | 127 | 432 | 147 | 323 | 86 |

| 8" | 243 | 333 | 536 | 305 | 254 | 218 | 197 | 147 | 470 | 203 | 361 | 127 |

| 10" | 297 | 335 | 538 | 310 | 254 | 218 | 197 | 167 | 547 | 251 | 465 | 156 |

| 12" | 338 | 338 | 541 | 312 | 254 | 218 | 197 | 184 | 610 | 277 | 500 | 184 |

| Equipped with a piston-type actuator Unit: mm |

| DN | A | B | C | D | E | F | G | H | J | K | L | weight

(Kg) |

| Flangeless | Flangeless |

| 6" | 229 | 330 | 677 | 302 | 254 | 271 | 213 | 127 | 432 | 147 | 297 | 194 |

| 8" | 243 | 333 | 680 | 305 | 254 | 271 | 216 | 147.5 | 470 | 203 | 335 | 236 |

| 10" | 297 | 335 | 683 | 310 | 254 | 271 | 221 | 167 | 574 | 251 | 440 | 263 |

| 12" | 338 | 338 | 686 | 312 | 254 | 271 | 224 | 184 | 610 | 277 | 475 | 290 |

| JB | PN1.6 | PN4.0 | PN6.4 |

| Specification Diameter | M×L | b | Number of Bolts | Number of Nuts | M×L | b | Number of Bolts | Number of Nuts | M×L | b | Number of Bolts | Number of Nuts |

| 25 | M12×170 | 30 | 4 | 8 | M12×175 | 35 | 4 | 8 | M16×195 | 35 | 4 | 8 |

| 40 | M16×190 | 35 | 4 | 8 | M16×200 | 35 | 4 | 8 | M20×215 | 40 | 4 | 8 |

| 50 | M16×210 | 35 | 4 | 8 | M16×215 | 35 | 4 | 8 | M20×230 | 40 | 4 | 8 |

| 80 | M16×250

M16×85* | 3525 | 4 | 8 | M16×260

M16×90* | 4030 | 72 | 142 | M20×280

M20×100* | 4035 | 72 | 142 |

| 100 | M16×280

M16×95* | 4030 | 7

2 | 142 | M20×300

M20×105* | 4035 | 72 | 142 | M22×315

M22×115* | 4535 | 72 | 142 |

| 150 | M20×330

M20×90* | 4035 | 72 | 142 | M22×350

M22×100* | 4540 | 72 | 142 | M30×380

M30×115* | 5045 | 72 | 142 |

| 200 | M20×350

M20×100* | 4040 | 104 | 204 | M27×390

M27×115* | 4545 | 104 | 204 | M30×410

M30×125* | 5045 | 104 | 204 |

| 250 | M22×420

M22×105* | 4040 | 88 | 168 | M30×455

M30×120* | 4545 | 88 | 168 | M36×480

M36×135* | 5050 | 88 | 168 |

| 300 | M22×460

M22×105* | 4540 | 88 | 168 | M30×500

M30×130* | 4545 | 128 | 248 | M36×530

M36×145* | 5050 | 128 | 248 |

| Note: Items marked with "*" are short double-ended studs. |

| b represents the thread length of the double-ended stud |

| JB | PN2.5 | | |

| Specification Diameter | M×L | b | Number of Bolts | Number of Nuts | | | | | | | | |

| 25 | M12×170 | 30 | 4 | 8 | | | | | | | | |

| 40 | M16×195 | 35 | 4 | 8 | | | | | | | | |

| 50 | M16×210 | 35 | 4 | 8 | | | | | | | | |

| 80 | M16×255

M16×90* | 35 30 | 7 2 | 14 2 | | | | | | | | |

| 100 | M20×295

M20×105* | 40 30 | 7 2 | 14 2 | | | | | | | | |

| 150 | M22×345

M22×90* | 40 35 | 7 2 | 14 2 | | | | | | | | |

| 200 | M22×370

M22×100* | 40 40 | 10 4 | 20 4 | | | | | | | | |

| 250 | M27×435

M27×105* | 40 40 | 8 8 | 16 8 | | | | | | | | |

| 300 | M27×475

M27×110* | 45 40 | 12 8 | 24 8 | | | | | | | | |

| List of Bolts and Nuts for Globe Valve-Pipeline Connection |

| ANSI | 150# | 300# | 600# |

| Specification Diameter | M×L | b | Number of Bolts | Number of Nuts | M×L | b | Number of Bolts | Number of Nuts | M×L | b | Number of Bolts | Number of Nuts |

| 25 | M14×185 | 30 | 4 | 8 | M16×195 | 35 | 4 | 8 | M18×210 | 40 | 4 | 8 |

| 40 | M14×200 | 30 | 4 | 8 | M20×225 | 40 | 4 | 8 | M20×235 | 40 | 4 | 8 |

| 50 | M16×225 | 35 | 4 | 8 |

M16×230

M16×95* | 40 |

7

2 |

14

2 |

M18×250

M18×105* | 40 |

7

2 |

14

2 |

| 80 | M18×270 | 35 | 4 | 8 |

M20×305

M20×130* | 40 |

7

2 |

14

2 |

M20×310

M20×140* | 40 |

7

2 |

14

2 |

| 100 |

M18×295

M18×105* | 40 |

7

2 |

14

2 |

M20×320

M20×135* | 40 |

7

2 |

14

2 |

M22×355

M22×150* | 45 |

7

2 |

14

2 |

| 150 |

M20×355

M20×120* | 40 |

7

2 |

14

2 |

M20×365

M20×150* | 45 |

11

2 |

22

2 |

M27×420

M27×170* | 50 |

11

2 |

22

2 |

| 200 |

M20×365

M20×105* | 40 |

6

4 |

12

4 |

M24×405

M24×125* |

50

45 |

10

4 |

20

4 |

M30×460

M30×150* |

55

45 |

10

4 |

20

4 |

| 250 |

M22×425

M22×110* | 40 |

8

8 |

16

8 |

M27×475

M27×130* |

50

45 |

12

8 |

24

8 |

M33×535

M33×165* |

65

45 |

12

8 |

24

8 |

| 300 |

M22×470

M22×110* | 45 |

8

8 |

16

8 |

M30×525

M30×140* |

65

45 |

12

8 |

24

8 |

M33×580

M33×165* |

65

50 |

16

8 |

32

8 |

| Note: The item marked with "*" is a short double-ended stud. |