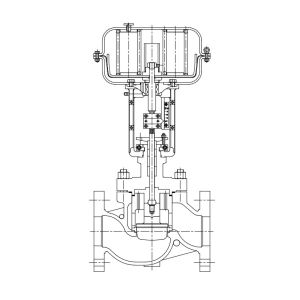

V100-SGN Series Low Noise Single Seated Control Valve features top guide and quick change trim design. As an extended production of SGP Single Seated Control Valve, it possesses not only the characteristics of SGP, but also other advantages such as noise reduction, anti-cavitation and so on. These two series have interchangeable trim parts.

The standard actuator configuration is multi-spring diaphragm; other actuator types such as cylinder, electric and hydraulic are also available.

Rated Cv and Stroke (Table2)

valve size

inch(mm) |

inch(mm) |

Rated Cv |

stroke(mm) |

valve size

inch(mm) |

inch(mm) |

Rated Cv |

stroke(mm) |

| EQ-% 1-Stage | LINEAR 1-Stage |

| 1/2 (15) | 1/2 (13) | 3 | 20 | 1/2 (15) | 1/2 (13) | 3 | 20 |

| 3/4 (20) | 3/4 (20) | 7 | 20 | 3/4 (20) | 3/4 (20) | 7 | 20 |

| 5/8 (16) | 5 | 20 | 5/8 (16) | 5 | 20 |

| 1/2 (13) | 3 | 20 | 1/2 (13) | 3 | 20 |

| 1 (25) | 1 (25) | 11 | 20 | 1 (25) | 1 (25) | 11 | 20 |

| 3/4 (20) | 7 | 20 | 3/4 (20) | 7 | 20 |

| 5/8 (16) | 5 | 20 | 1/2 (15) | 5 | 20 |

| 1 1/2 (40) | 1 1/2 (40) | 22 | 20 | 1 1/2 (40) | 1 1/2 (40) | 25 | 20 |

| 1 1/4 (32) | 17 | 20 | 1 1/4 (32) | 17 | 20 |

| 1 (25) | 11 | 20 | 1 (25) | 11 | 20 |

| 2 (50) | 2 (50) | 36 | 30 | 2 (50) | 2 (50) | 40 | 30 |

| 1 1/2 (40) | 22 | 30 | 1 1/2 (40) | 25 | 30 |

| 1 1/4 (32) | 17 | 30 | 1 1/4 (32) | 17 | 30 |

| 2 1/2 (65) | 2 1/2 (65) | 55 | 30 | 2 1/2 (65) | 2 1/2 (65) | 65 | 30 |

| 2 (50) | 36 | 30 | 2 (50) | 40 | 30 |

| 1 1/2 (40) | 22 | 30 | 1 1/2 (40) | 25 | 30 |

| 3 (80) | 3 (80) | 80 | 40 | 3 (80) | 3 (80) | 100 | 40 |

| 2 1/2 (65) | 70 | 40 | 2 1/2 (65) | 70 | 40 |

| 2 (50) | 40 | 40 | 2 (50) | 40 | 40 |

| 4 (100 | 4 (100 | 130 | 40 | 4 (100 | 4 (100 | 150 | 40 |

| 3 (80) | 80 | 40 | | 3 (80) | 100 | 40 |

| 2 1/2 (65) | 70 | 40 | | 2 1/2 (65) | 70 | 40 |

| 5 (125) | 5 (125) | 220 | 60 | 5 (125) | 5 (125) | 280 | 60 |

| 4 (100 | 170 | 60 | | 4 (100 | 170 | 60 |

| 3 (80) | 100 | 60 | | 3 (80) | 100 | 60 |

| 6 (150) | 6 (150) | 250 | 60 | 6 (150) | 6 (150) | 320 | 60 |

| 5 (125) | 220 | 60 | 5 (125) | 280 | 60 |

| 4 (100 | 170 | 60 | 4 (100 | 170 | 60 |

| EQ-% 2-Stage | LINEAR 2-Stage |

| 1 (25) | 3/4 (20) | 7 | 20 | 1 (25) | 3/4 (20) | 7 | 20 |

| 1 1/2 (40) | 1 1/4 (32) | 17 | 20 | 1 1/2 (40) | 1 1/4 (32) | 17 | 20 |

| 1 (25) | 11 | 20 | 1 (25) | 11 | 20 |

| 2 (50) | 1 1/2 (40) | 22 | 30 | 2 (50) | 1 1/2 (40) | 25 | 30 |

| 1 1/4 (32) | 17 | 30 | 1 1/4 (32) | 17 | 30 |

| 1 (25) | 11 | 30 | 1 (25) | 11 | 30 |

| 2 1/2 (65) | 2 (50) | 36 | 30 | 2 1/2 (65) | 2 (50) | 40 | 30 |

| 1 1/2 (40) | 22 | 30 | 1 1/2 (40) | 25 | 30 |

| 1 1/4 (32) | 17 | 30 | 1 1/4 (32) | 17 | 30 |

| 3 (80) | 2 1/2(65) | 70 | 40 | 3 (80) | 2 1/2(65) | 70 | 40 |

| 2 (50) | 40 | 40 | 2 (50) | 40 | 40 |

| 1 1/2 (40) | 22 | 40 | 1 1/2 (40) | 25 | 40 |

| 4 (100 | 3 (80) | 80 | 40 | 4 (100 | 3 (80) | 100 | 40 |

| 2 1/2(65) | 70 | 40 | 2 1/2(65) | 70 | 40 |

| 2 (50) | 40 | 40 | 2 (50) | 40 | 40 |

| 5 (125) | 4 (100) | 170 | 60 | 5 (125) | 4 (100) | 170 | 60 |

| 3 (80) | 100 | 60 | 3 (80) | 100 | 60 |

| 2 1/2(65) | 70 | 60 | 2 1/2(65) | 70 | 60 |

| 6 (150) | 5 (125) | 220 | 60 | 6 (150) | 5 (125) | 280 | 60 |

| 4 (100) | 170 | 60 | 4 (100) | 170 | 60 |

| 3 (80) | 100 | 60 | 3 (80) | 100 | 60 |

| EQ-% 3-Stage | LINEAR 3-Stage |

| 1 1/2 (40) | 3/4 (20) | 7 | 20 | 1 1/2 (40) | 3/4 (20) | 7 | 20 |

| 2 (50) | 1 (25) | 11 | 30 | 2 (50) | 1 (25) | 11 | 30 |

| 2 1/2 (65) | 1 1/2 (40) | 22 | 30 | 2 1/2 (65) | 1 1/2 (40) | 25 | 30 |

| 3 (80) | 2 (50) | 40 | 40 | 3 (80) | 2 (50) | 40 | 40 |

| 4 (100 | 2 1/2(65) | 70 | 40 | 4 (100 | 2 1/2(65) | 70 | 40 |

| 5 (125) | 3 (80) | 100 | 60 | 5 (125) | 3 (80) | 100 | 60 |

| 6 (150) | 4 (100) | 170 | 60 | 6 (150) | 4 (100) | 170 | 60 |

Body Material Temperature - Pressure Range (Table 3)

standard working pressure MPa

| 600LB | 300LB | 150LB | 温度℃

Temperature |

| CF8M | CF8 | WC9 | WC6 | WCB | CF8M | CF8 | WC9 | WC6 | WCB | CF8M | CF8 | WC9 | WC6 | WCB |

| 9.93 | 9.92 | 10.34 | 10.34 | 10.21 | 4.96 | 4.96 | 5.17 | 5.17 | 5.11 | 1.90 | 1.90 | 2.00 | 2.00 | 1.96 | -29~38 |

| 9.63 | 9.57 | 10.24 | 10.23 | 10.02 | 4.81 | 4.78 | 5.12 | 5.11 | 5.01 | 1.84 | 1.84 | 1.92 | 1.92 | 1.92 | 50 |

| 8.44 | 8.18 | 9.81 | 9.75 | 9.28 | 4.22 | 4.09 | 4.90 | 4.88 | 4.64 | 1.62 | 1.57 | 1.77 | 1.77 | 1.77 | 100 |

| 7.70 | 7.27 | 9.33 | 9.27 | 9.05 | 3.85 | 3.63 | 4.66 | 4.64 | 4.52 | 1.48 | 1.39 | 1.58 | 1.58 | 1.58 | 150 |

| 7.13 | 6.55 | 8.97 | 9.10 | 8.76 | 3.77 | 3.28 | 4.48 | 4.55 | 4.38 | 1.37 | 1.26 | 1.40 | 1.40 | 1.40 | 200 |

| 6.68 | 6.11 | 8.84 | 8.89 | 8.34 | 3.34 | 3.05 | 4.42 | 4.45 | 4.17 | 1.21 | 1.17 | 1.21 | 1.20 | 1.21 | 250 |

| 6.33 | 5.81 | 8.49 | 8.49 | 7.75 | 3.16 | 2.91 | 4.24 | 4.24 | 3.87 | 1.02 | 1.02 | 1.02 | 1.02 | 1.02 | 300 |

| 6.08 | 5.61 | 8.05 | 8.05 | 7.39 | 3.04 | 2.81 | 4.02 | 4.02 | 3.70 | 0.84 | 0.84 | 0.84 | 0.84 | 0.84 | 350 |

| 5.94 | 5.55 | 7.76 | 7.76 | 7.29 | 2.97 | 2.78 | 3.88 | 3.88 | 3.65 | 0.74 | 0.74 | 0.74 | 0.74 | 0.74 | 375 |

| 5.82 | 5.49 | 7.32 | 7.32 | 6.90 | 2.91 | 2.75 | 3.66 | 3.66 | 3.45 | 0.65 | 0.65 | 0.65 | 0.65 | 0.65 | 400 |

| 5.73 | 5.43 | 7.02 | 7.02 | 5.75 | 2.87 | 2.72 | 3.51 | 3.51 | 2.88 | 0.56 | 0.56 | 0.56 | 0.56 | 0.56 | 425 |

| 5.62 | 5.37 | 6.76 | 6.76 | | 2.81 | 2.69 | 3.38 | 3.38 | | 0.47 | 0.47 | 0.47 | 0.47 | / | 450 |

| 5.47 | 5.31 | 6.33 | 6.33 | | 2.74 | 2.66 | 3.17 | 3.17 | | 0.37 | 0.37 | 0.37 | 0.37 | / | 475 |

| 5.37 | 5.21 | 5.56 | 5.56 | | 2.68 | 2.61 | 2.78 | 2.78 | | 0.28 | 0.28 | 0.28 | 0.28 | / | 500 |

| 5.16 | 4.78 | 4.38 | 4.05 | | 2.58 | 2.39 | 2.19 | 2.03 | | 0.19 | 0.19 | 0.19 | 0.19 | / | 525 |

| 4.99 | 4.36 | 3.27 | | | 2.50 | 2.18 | 1.64 | | | 0.13 | 0.13 | 0.13 | | / | 550 |

| 4.82 | 4.01 | 2.34 | | | 2.41 | 2.01 | 1.17 | | | 0.13 | 0.13 | 0.13 | | / | 575 |

Trim Material Temperature Range (Table 4)

No. |

Material | ℃

Temperature

Range |

Remark |

| 1 | 410 | -29~427 |

Heat treatment |

| 2 | 440 | -29~427 |

Heat treatment |

| 3 | 17-4PH | -29~427 |

Heat treatment |

| 4 | INCONEL718 | -29~620 | |

| 5 | F11+STF | -29~510 |

Partial or all stellite alloy overlay welding

according to requirements |

| 6 | F22+STF | -29~550 |

Partial or all stellite alloy overlay welding

according to requirements |

| 7 | F91+STF | -29~620 |

Partial or all stellite alloy overlay welding

according to requirements |

| 8 | 304 | -196~538 |

Partial or all stellite alloy overlay welding

according to requirements |

| 9 | 316 | -196~538 |

Partial or all stellite alloy overlay welding

according to requirements |

| 10 | 304L | -196~538 |

Partial or all stellite alloy overlay welding

according to requirements |

| 11 | 316L | -196~538 |

Partial or all stellite alloy overlay welding

according to requirements |

Valve Internal Structure

| No. | Name | (Q’ty) |

| 1 | body | 1 |

| 2 | bonnet | 1 |

| 3 | seat | 1 |

| 4 | plug | 1 |

| 5 | stem | 1 |

| 6 | guide | 1 |

| 13 | seat gasket | 1 |

| 14 | bonnet gasket | 1 |

| 15 | packing | 1 |

| 16 | packing | 1 |

| 17 | stem guide | 1 |

| 18 | packing follower | 1 |

| 19 | packing flange | 1 |

Allowable differential pressure (Table5)

Diaphragm Actuator/PTFE Packing

DA:Direct action MPa

| 550 | 480 | 370 | 290 | 250 |

Actuator specification |

| 0.36 | 0.36 | 0.36 | 0.28 | 0.28 |

Supply pressure MPa |

| 80-210/60 | 110-220/40

80-250/60 | 130~230/20

80~230/30

80~280/40 | 60~170/20

60~220/30 | 60~220/20 | kPa

Spring range mm

Stroke |

VI |

V |

IV |

VI |

V |

IV |

VI |

V |

IV |

VI |

V |

IV |

VI |

V |

IV |

Sealing surface Leakage |

| | | | | | | | | | 3.0 | 10 | 10 | 3.0 | - | 6.6 | 13 | 1/2 |

Seat Size

inch/

mm |

| | | | | | | 3.0 | 10 | 10 | 3.0 | 6.6 | 10 | 3.0 | - | 4.5 | 16 | 5/8 |

| | | | | | | 3.0 | 10 | 10 | 3.0 | 3.0 | 10 | 3.0 | | 3.1 | 20 | 3/4 |

| | | | | | | 3.0 | 10 | 10 | 3.0 | 1.0 | 8.0 | 2.1 | - | 2.1 | 25 | 1 |

| | | | | | | 3.0 | 3.2 | 8.2 | 3.0 | - | 4.0 | | | | 32 | 1-1/4 |

| | | | | | | 3.0 | 2.2 | 7.0 | 3.0 | - | 3.2 | | | | 40 | 1-1/2 |

| | | | | | | 3.0 | 0.8 | 3.8 | 0.4 | - | 0.4 | | | | 50 | 2 |

| | | | | | | 2.2 | 0.4 | 2.2 | | | | | | | 65 | 2-1/2 |

| | | | 3.0 | 0.8 | 3.3 | 0.7 | - | 0.7 | | | | | | | 80 | 3 |

| | | | 1.7 | 0.2 | 1.7 | 0.2 | - | 0.2 | | | | | | | 100 | 4 |

| 0.9 | - | 0.9 | 0.4 | - | 0.4 | | | | | | | | | | 125 | 5 |

| 0.5 | - | 0.5 | 0.2 | - | 0.2 | | | | | | | | | | 150 | 6 |

Diaphragm Actuator/Graphite Packing

DA:Direct action MPa

| 550 | 480 | 370 | 290 | 250 |

Actuator specification |

| 0.36 | 0.36 | 0.36 | 0.28 | 0.28 |

Supply pressure MPa |

| 80-210/60 | 110-220/40

80-250/60 | 130~230/20

80~230/30

80~280/40 | 60~170/20

60~220/30 | 60~220/20 | kPa

Spring range mm Stroke |

V |

IV |

V |

IV |

V |

IV |

V |

IV |

V |

IV |

Sealing surface Leakage |

| | | | | | | 10 | 10 | - | 5.7 | 13 | 1/2 |

Seat Size

inch/mm |

| | | | | 10 | 10 | 5.7 | 10 | - | 3.9 | 16 | 5/8 |

| | | | | 10 | 10 | 2.3 | 9.3 | - | 2.4 | 20 | 3/4 |

| | | | | 9.7 | 10 | 0.5 | 7.5 | - | 1.6 | 25 | 1 |

| | | | | 3.0 | 7.8 | - | 3.8 | | | 32 | 1-1/4 |

| | | | | 2.0 | 6.7 | - | 3.0 | | | 40 | 1-1/2 |

| | | | | 0.7 | 3.7 | - | 0.3 | | | 50 | 2 |

| | | | | 0.3 | 2.1 | | | | | 65 | 2-1/2 |

| | | 0.7 | 3.2 | 一 | 0.6 | | | | | 80 | 3 |

| | | 0.2 | 1.6 | - | 0.2 | | | | | 100 | 4 |

| - | 0.9 | | 0.4 | | | | | | | 125 | 5 |

| - | 0.5 | - | 0.2 | | | | | | | 150 | 6 |

Diaphragm Actuator/PTFE Packing

RA:Reverse action

| 480 | 370H | 370 | 290 | 250 |

Actuator specification |

| 0.36 | 0.40 | 0.36 | 0.28 | 0.28 |

Supply pressure MPa |

140-250/40

110-280/60 | 194-352/30

142-352/40 | 130~230/20

130~280/30

80~280/40 | 110~220/20

60~220/30 | 60~220/20 | kPa

Spring range mm

Stroke |

VI |

V |

IV |

VI |

V |

IV |

VI |

V |

IV |

VI |

V |

IV |

VI |

V |

IV |

Sealing surface Leakage |

| | | | | | | | | | 3.0 | 10 | 10 | 3.0 | - | 6.6 | 13 | 1/2 |

Seat Size

inch/

mm |

| | | | | | | 3.0 | 10 | 10 | 3.0 | 6.6 | 10 | 3.0 | - | 4.5 | 16 | 5/8 |

| | | | | | | 3.0 | 10 | 10 | 3.0 | 3.0 | 10 | 3.0 | - | 3.1 | 20 | 3/4 |

| | | | | | | 3.0 | 10 | 10 | 3.0 | 1.0 | 8.0 | 2.1 | - | 2.1 | 25 | 1 |

| | | | | | | 3.0 | 3.2 | 8.2 | 3.0 | - | 4.0 | | | | 32 | 1-1/4 |

| | | | | | | 3.0 | 2.2 | 7.0 | 3.0 | - | 3.2 | | | | 40 | 1-1/2 |

| | | | 3.0 | 2.3 | 6.1 | 3.0 | 0.8 | 3.8 | 0.4 | - | 0.4 | | | | 50 | 2 |

| | | | 3.0 | 0.6 | 3.6 | 2.2 | 0.4 | 2.2 | | | | | | | 65 | 2-1/2 |

| 3.0 | 0.7 | 3.2 | 1.6 | 0.1 | 1.6 | 0.7 | - | 0.7 | | | | | | | 80 | 3 |

| 1.6 | 0.2 | 1.6 | 0.8 | - | 0.8 | 0.2 | - | 0.2 | | | | | | | 100 | 4 |

| 0.4 | - | 0.4 | | | | | | | | | | | | | 125 | 5 |

| 0.2 | - | 0.2 | | | | | | | | | | | | | 150 | 6 |

Diaphragm Actuator/PTFE Packing(continued)

RA:Reverse action MPa

| 550 | 480H |

Actuator specification |

| 0.36 | 0.36 |

Supply pressure MPa |

| 140-280/60 | 120-280/60 | kPa

Spring range mm Stroke |

VI |

V |

IV |

VI |

V |

IV |

Sealing surface Leakage |

| | | | | | | 13 | 1/2 | |

| | | | | | | 16 | 5/8 |

| | | | | | | 20 | 3/4 |

| | | | | | | 25 | 1 |

| | | | | | | 32 | 1-1/4 |

| | | | | | | 40 | 1-1/2 |

| | | | | | | 50 | 2 | inch/mm |

| | | | | | | 65 | 2-1/2 |

| | | | | | | 80 | 3 |

| | | | | | | 100 | 4 |

| 0.9 | - | 0.9 | 0.8 | - | 0.8 | 125 | 5 |

| 0.5 | , | 0.5 | 0.4 | - | 0.4 | 150 | 6 |

Diaphragm Actuator/Graphite Packing

RA:Reverse action MPa

| 550 | 480H | 480 | 370H | 370 | 290 | 250 |

Actuator specification |

| 0.36 | 0.36 | 0.36 | 0.40 | 0.36 | 0.28 | 0.28 |

Supply pressure MPa |

| 140-280/60 | 120-280/60 | 140-250/40

110-280/60 | 194-352/30

142-352/40 | 130~230/20

130~280/30

80~280/40 | 110~220/20

60~220/30 | 60~220/20 | kPa

Spring range mm

Stroke |

V |

IV |

V |

IV |

V |

IV |

V |

IV |

V |

IV |

V |

IV |

V |

IV |

Sealing surface Leakage |

| | | | | | | | | | | 10 | 10 | | 6.6 | 13 | 1/2 |

Seat Size

inch/

mm |

| | | | | | | | | 10 | 10 | 6.6 | 10 | - | 4.5 | 16 | 5/8 |

| | | | | | | | | 10 | 10 | 3.0 | 10 | - | 3.1 | 20 | 3/4 |

| | | | | | | | | 10 | 10 | 1.0 | 8.0 | - | 2.1 | 25 | 1 |

| | | | | | | | | 3.2 | 8.2 | 一 | 3.8 | | | 32 | 1-1/4 |

| | | | | | | | | 2.2 | 7.0 | - | 3.0 | | | 40 | 1-1/2 |

| | | | | | | 2.3 | 6.1 | 0.8 | 3.8 | - | 0.4 | | | 50 | 2 |

| | | | | | | 0.6 | 3.6 | 0.4 | 2.2 | | | | | 65 | 2-1/2 |

| | | | | 0.7 | 3.2 | 0.1 | 1.6 | 一 | 0.7 | | | | | 80 | 3 |

| | | | | 0.2 | 1.6 | 一 | 0.8 | - | 0.2 | | | | | 100 | 4 |

| - | 0.9 | - | 0.7 | - | 0.4 | | | | | | | | | 125 | 5 |

| | 0.5 | - | 0.4 | | 0.2 | | | | | | | | | 150 | 6 |

External Dimensions(Table6)

Body Size | L | H |

| ANSI150LB | ANSI300LB | ANSI600LB | standard type | heat sink type |

| INCH | DN | RF | RJ |

Welded | RF | RJ |

Welded | RF | RJ |

Welded |

| 1/2 | 15 | 184 | 184 | 206 | 190 | 190 | 206 | 203 | 203 | 206 | 124 | 224 |

| 3/4 | 20 | 184 | 184 | 210 | 194 | 194 | 210 | 206 | 206 | 210 | 124 | 224 |

| 1 | 25 | 184 | 184 | 210 | 197 | 197 | 210 | 210 | 210 | 210 | 124 | 224 |

| 11/2 | 40 | 222 | 222 | 251 | 235 | 235 | 251 | 251 | 251 | 251 | 145 | 245 |

| 2 | 50 | 254 | 257 | 286 | 267 | 270 | 286 | 286 | 289 | 286 | 156 | 256 |

| 21/2 | 65 | 276 | 279 | 292 | 292 | 295 | 292 | 311 | 314 | 311 | 195 | 295 |

| 3 | 80 | 298 | 301 | 318 | 318 | 321 | 318 | 337 | 340 | 337 | 210 | 310 |

| 4 | 100 | 352 | 355 | 368 | 368 | 371 | 368 | 394 | 397 | 394 | 235 | 335 |

| 5 | 125 | 403 | 406 | 425 | 425 | 428 | 425 | 457 | 460 | 457 | 302 | 372 |

| 6 | 150 | 451 | 454 | 473 | 473 | 476 | 473 | 508 | 511 | 508 | 326 | 396 |

Actuator Size | E | C | D | F |

| 250 | 252 | 343 | 168 | - |

| 290 | 292 | 369 | 214 | - |

| 370 | 370 | 409 | 214 | |

| 370H | 370 | 440 | 214 | |

| 480 | 482 | 628 | - | 350 |

| 480H | 482 | 680 | - | 387 |

| 550 | 560 | 703 | - | 387 |

WEYO AUTO TECH

High-End Die-Shanghai WEYO Automation Technology Co., Ltd. was established in

2021 and is headquartered in Shanghai. It is an innovative

technology enterprise that specializes in high-end industrial

automation equipment, core components supply, technical services,

and solution provision. With the core philosophy of "Technology

Drives Efficiency, Service Creates Value," WEYO is dedicated to

offering high-performance die-casting equipment, precision

components, and intelligent system integration services to global

manufacturing clients, helping them achieve optimized production

processes and upgrades.