We are a company with many years of experience in the production of

special precision ceramics and the ability to design, manufacture,

process and sell structural and functional parts of various special

precision ceramics.

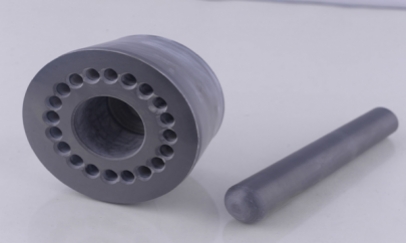

Deyu Precision Ceramics Technology Co., Ltd. has many years of

experience in producing special precision ceramics, and has the

ability to design, manufacture, process and sell structural and

functional parts of various special precision ceramics. At present,

the company has production and processing equipment such as dry

press, isostatic press, experimental furnace, flat kiln, machining

center, surface grinder, universal internal and external grinder,

centerless grinder and laser cutting machine, as well as complete

high-precision testing equipment such as high-precision projector,

three-dimensional tester, metallographic microscope, hardness

tester and densitometer.

With advanced production technology and complete production

facilities, the company is one of the few domestic enterprises that

can produce special precision ceramic structural parts and

functional parts with machining accuracy less than 2 microns, and

has strong core competitiveness in the same industry in China.

Advantages of the company: 1. National new technology enterprises;

2. The company has a municipal R&D center; 3. Cooperation with

domestic key universities and research institutes; 4. Design,

molding, sintering and precision processing; 5. The products cover

alumina, zirconia, silicon nitride, silicon carbide and other

precision ceramics; 6. Precision plus technology.

The company has always been standing in the position of customers

to solve problems, focusing on the principle of quality and

delivery time, adhering to the business philosophy of "integrity,

innovation and reassurance", and sincerely looking forward to

cooperating with you.