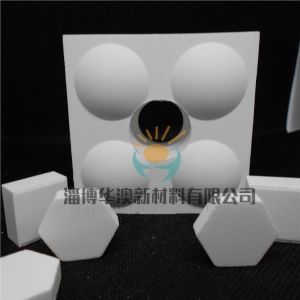

Alumina Ceramic Lining

Products Introduction

Alumina Ceramic Lining are made with high alumina under 1500 degree

temperature firing in kiln. It has high compression strength, low

wear resistance and high hardness. There are all kinds of shape,

such as square, rectangle, sleeve,cylinder and some special shape.

Alumina Ceramic Lining is one of the most stable chemical

properties and the highest mechanical strength among refractory

oxides; Alumina ceramic does not react with most molten metals,

only Mg, Ca, Zr and Ti could have a reducing effect on it above a

certain temperature; hot Sulfuric acid can dissolve alumina, and

hot HCl and HF also have some corrosive effect on it; the vapor

pressure and decomposition pressure of alumina ceramics are the

smallest.

Wear resistant alumina ceramic linings is good liner for mineral

equipment, can be used in cyclone, pipe, bend, discharge,ball mill,

etc. Including 92%, 95% and ZTA series products.

HUAO's wear resistant alumina ceramic tiles can be cut into any

shape and are easy to install and maintain. They are suitable for

both wet and dry processing applications. Advanced ceramics combine

high strength and toughness with extreme hardness to deliver

exceptional wear resistance.

Products Parameter

Item/Product | HA92% | HA95% |

Al2O3 (%) | 92±0.5 | 95±0.5 |

Bending Strength(MPa) | ≥220 | >280 |

Fracture Toughness (MPam ½) | >3.6 | >3.9 |

Rockwell Hardness (HRA) | >82 | >88 |

Wear Volum (cm3) | <0.5 | <0.3 |

Density (g/cm3) | >3.6 | >3.7 |

Viker Hardness (Hv50) | ≥1050 | ≥1150 |

application

1. In Power Plant

| System | Application |

Coal conveying system | Coal conveying pipeline |

Belt joint hopper |

Coal hopper |

Raw coal hopper |

Coal feeder |

Coal pulverizing system | Coal mill drum |

Chute and hopper lining |

Outlet pipeline |

Primary air pipe and elbow |

Pulverized coal pipe and elbow |

Burner pipeline |

Dust removing/disposing system | Dust removing pipe and elbow |

Fine fly ash pipe |

Slay removal |

Dry ash pipe |

Limestone crushing and raw fuel preblending system | Chute |

Hopper |

Raw fuel grinding, homogenization and storage system | Vertical mill feed chute |

Vertical mill air-intake lining board |

Vertical mill scraper plate |

Separator |

Cyclone |

Fan impeller and shell |

Mill outlet elbow and expansion joint |

Firing system | Tertiary air duct |

Elbow of the inlet or outlet of humidifier tower |

Elbow from grate cooler to electrostatic precipitator |

Kiln head electrostatic precipitator tail air pipe elbow |

Discharge |

Cement grinding system | Vertical mill feed chute |

Mill outlet elbow and expansion joint |

2. In Mineral Processing Industry

| System | Application area |

Materials conveying system | Concentrate pipeline |

Tailing pipeline |

Backfill mineral |

Grinding system | Chute and hopper lining |

Outlet pipeline |

Mineral processing system | Vibrating chute |

Cyclone |

Entrifugal dehydrator |

3.In Steel Industry

| System | Application area |

Material conveying system | Hopper |

Bunker lining |

Mixing bine |

Compounding ingredients system | Primary mixing drum |

Secondary mixing drum |

Sintered materials conveying system | Mineral processing hopper under vibrating screen |

Long distance mineral processing hopper and bunker |

Dust removal and discharge system | Dust removing pipe |

Dust collecting pipe |

Machine tail dust removing pipe |

4. In Coal Preparation Industry

| System | Application area |

Conveying system | Medium conveying pipeline |

Coal washery equipment feeding pipeline |

Coal washery equipment discharge pipeline |

Non-pressure gravity flow pipeline |

Coal washery conveying pipeline |

Mining equipment | Horizontal screen bowl centrifuge |

Horizontal vibratory screen centrifuge |

Horizontal coal slurry scroll/screen centrifuge |

Automatic flocculent make-up system |

Cyclone |

Products show

factory show

Product quality certification

fAQ

· What are the benefits of alumina ceramic lining?

Alumina ceramic lining provides many benefits, including:

- Increased wear resistance

- Improved corrosion resistance

- Reduced downtime and maintenance costs

- Longer equipment lifespan

- Enhanced productivity and efficiency

· What types of equipment can be lined with alumina ceramic?

Alumina ceramic lining can be applied to a wide range of equipment,

including:

- Pipes and fittings

- Cyclones and separators

- Ball mills and agitators

- Chutes and hoppers

- Fans and blowers

- Dust collectors and scrubbers

· How is alumina ceramic lining applied?

Alumina ceramic lining is typically applied using a bonding

material, such as epoxy or a ceramic adhesive. The ceramic lining

is carefully cut to fit the equipment surface and then bonded in

place. The surface may need to be prepared with a primer or surface

roughening for optimal adhesion.