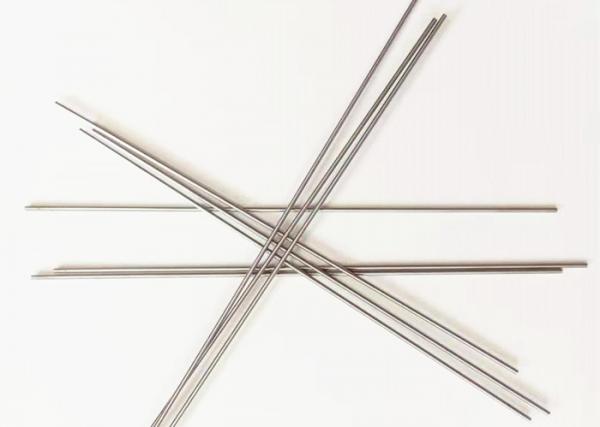

Micro Drills Usage Polishing Tungsten Carbide Round Bar / Hard

Metal Rod

Micro Drills Usage Polishing Tungsten Carbide Round Bar / Hard

Metal rod

We can supply all kinds of dimensions solid carbide rods with

fine&sub micron grain size We manufactured and stocked many

dimensions of ground and unground carbide rod for your.

Application of tungsten carbide round bar

Our tungsten carbide rod manufactured with high hardness and

toughness, vibration-resistance, especially no stick when working.

It is widely used for making

- various kinds of carbide solid tools and cutting tools, such as

drills, end mills, thread taps, rotating file,etc.

- A good material for general-purpose. Suitable for machining

carbon steel, cast irons, stainless steel, heat-resistance steel,

nickel based alloys and titanium alloys.

- Tungsten Carbide wear Parts

- Tungsten Carbide Mouldingdies

Some key areas where cemented carbide components are used:

- Automotive components

- Rotary cutters for high-speed cutting of artificial fibres

- Metal forming tools for wire drawing and stamping application

- Rings and bushings typically for bump and seal applications

- Woodworking, e.g., for sawing and planingapplications

- Pump pistons for high-performance pumps (e.g., in

nuclearinstallations)

- Nozzles, e.g., high-performance nozzles for Oil drilling

applications

- Roof and tail tools and components for high wear resistance

- Balls for ball bearing and ball point pen

Production Info.

1. Hardness can reach to HRA 94 max, TRS ≥4000 N/mm²

2. Various dimension of the rods can be supplied, also can

customized as your requirements.

3. Blank rods and polished rods available

4. The minimum diameter is φd 0.3mm and the tolerance can reach to

±0.001mm.

5. Common diameter from 1mm---35mm

6. Blank Diameter tolerance: +0.3--0.8mm; length tolerance:

+0.3--1.8mm

7. Ground tolerance generally h5/h6, can based on your requirement.

Grade information

| Carbide Grade | ZF06C | ZF08C | ZF12C | ZF10CS | ZF10CF | ZF10C |

| WC | % | 94 | 92 | 88 | 90 | 90 | 90 |

| Co | % | 6 | 8 | 12 | 10 | 10 | 10 |

| Grain Size | μm | 0.4 | 0.4 | 0.4 | 0.4 | 0.6 | 0.8 |

| Density | g / c m³ | 14.85 | 14.65 | 14.25 | 14.4 | 14.4 | 14.4 |

| Hardness | HRA | 94 | 93.5 | 92.3 | 93 | 92.5 | 91.5 |

| TRS | N / m m² | 4000 | 4000 | 3800 | 3800 | 3600 | 3600 |

| Grade | Recommendation |

| ZF06C | This tungsten carbide rod is with 0.4μm ultrafine particles and CO

6%. Be suitable for processing aluminum- magnesium alloy, glass

fiber, carbon fiber, wood, hard plastic, etc. Recommend for making

micro tools and drills. |

| ZF08C | This tungsten carbide rod is with 0.4μm ultrafine particles and CO

8%. Be suitable for processing resin, wood, titanium alloy,

stainless steel, copper-aluminum alloy, composite material.

Recommend making high speed drill, end mill, graver and micro-drill

PCB with diameter less than 0.8mm. |

| ZF12C | This tungsten carbide rod is with 0.4μm ultrafine particles and CO

12%. Be suitable for semi-finishing and finishing process of

stainless steel, mold steel and normal titanium alloy, etc.

Recommend for making all types of high speed end mills, reamers and

gravers. |

| ZF10CS | This tungsten carbide rod is with 0 . 4 μ m ultrafine particles and

CO 12 %, higher hardness . Be suitable for finishing process of

stainless steel , mold steel and normal titanium alloy , etc .

Recommend for making all types of high speed end |

| ZF10CF | This tungsten carbide rod is with 0 . 6 μ m Sub - micron particles

and CO 10 %, which is widely used in cutting tools . Be suitable

for rough finishing , semi - finishing and finishing of mold steel

, grey cast iron , austenitic stainless steel and heat - resistant

alloy . Recommend for making normal drill and end mill |

| ZF10C | This tungsten carbide rod is with 0 . 8 μ m Sub - micron particles

and CO 10 %. Be suitable for rough finishing and semi - finishing

of normal steel , cast iron and stainless steel . Recommend for

making normal drill and end mill

|

Part Size List

| Grinding | Blank |

| D | L | D | L |

| (mm) | Tol.(mm) | Tol.(+1mm) | (mm) | Tol.(mm) | Tol.(+3mm) |

| 2 | h6 | 330 | 2.2 | +0.2 | 330 |

| 3 | h6 | 330 | 2.7 | +0.2 | 330 |

| 3.175 | h6 | 330 | 3.2 | +0.2 | 330 |

| 4 | h6 | 330 | 3.7 | +0.2 | 330 |

| 5 | h6 | 330 | 4.2 | +0.2 | 330 |

| 6.35 | h6 | 330 | 4.7 | +0.2 | 330 |

| 7 | h6 | 330 | 5.2 | +0.2 | 330 |

| 8 | h6 | 330 | 5.7 | +0.2 | 330 |

| 9 | h6 | 330 | 6.2 | +0.2 | 330 |

| 10 | h6 | 330 | 6.7 | +0.2 | 330 |

| 11 | h6 | 330 | 7.2 | +0.2 | 330 |

| 12 | h6 | 330 | 7.7 | +0.3 | 330 |

| 12.7 | h6 | 330 | 8.2 | +0.3 | 330 |

| 13 | h6 | 330 | 8.7 | +0.3 | 330 |

| 14 | h6 | 330 | 9.2 | +0.3 | 330 |

| 15 | h6 | 330 | 9.7 | +0.3 | 330 |

| 16 | h6 | 330 | 10.2 | +0.3 | 330 |

| 17 | h6 | 330 | 10.7 | +0.3 | 330 |

| 18 | h6 | 330 | 11.2 | +0.3 | 330 |

| 19 | h6 | 330 | 11.7 | +0.3 | 330 |

| 20 | h6 | 330 | 12.2 | +0.3 | 330 |

| 22.22 | h6 | 270 | 14.2 | +0.3 | 330 |

| 35 | h6 | 260 | 16.2 | +0.3 | 330 |

For more size information, please kindly email or call us

Product features:

1. Using100% virgin raw material guaranteed products quality

2. Our tugnsten carbide rods use dry isostatic pressing machine and

low press sintering technology, which showed uniform distribution

of cobalt magnetic, high hardness and bending strength.

3. Inner structure are more compact and well distributed in

metallographic test.

4. It can reach a mirror effect surface after accurate grinding.

5. Perfect quality control systerm: ISO9001:2015

6. customization is avaliable

Production Process:

Power mixing-Pressing-HIP sintering-Blank- Processing- Finished

Our packing

We guarantee:

* We are real factory in Zhuzhou

* Manufactured with100% tungsten carbide raw material

* Comply with ISO 9001:2015 Certification

* Rich experience of over 10 years

* Advanced technology , automatic pressing , HIP sintering

* Full ability to accept OEM & ODM orders

* Strict inspection for quality of raw material and finished

products