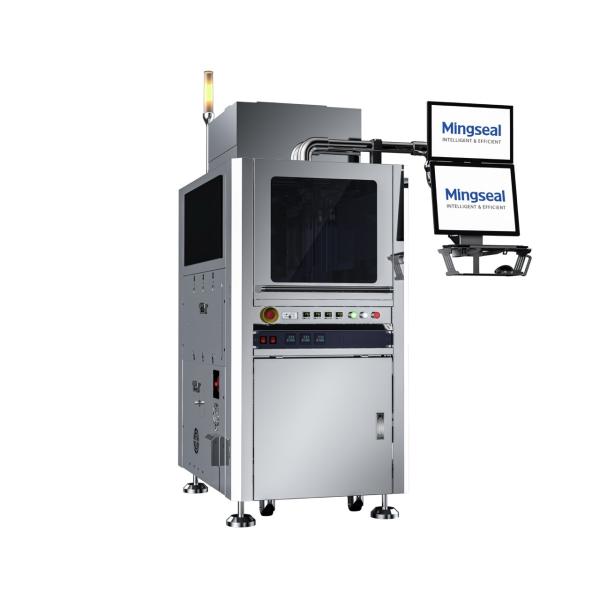

Advanced Packaging Wafer-Level Underfill & Flux Jetting Machine

The GS600SW Wafer-Level Underfill Dispenser is Mingseal’s flagship

dispensing module designed for next-generation wafer-level packaging (WLP) and advanced redistribution layer (RDL)

processes. Built to handle high-complexity underfill and flux spray

operations, it is ideal for Fan-Out Wafer-Level Packaging (FoWLP),

CoWoS, and FoPoP applications where ultra-high precision and

process consistency are mandatory.

Equipped with a high-stability linear motor transmission, precision

screw-driven Z-axis, and a fully integrated vision alignment

system, the GS600SW ensures micron-level dot placement and path

control. Its robust wafer chuck table delivers exceptional planarity and temperature uniformity—critical for void-free underfill performance.

In addition to underfill dispensing, the GS600SW can be configured

with an optional spray valve module to apply flux or adhesives

uniformly across wafer surfaces, increasing process flexibility for

manufacturers dealing with multi-step flip chip or RDL packaging

lines.

Core Advantages

Optimized for 8-inch & 12-inch Wafers

Supports standard 200mm and 300mm wafers with adjustable chuck

table and wafer cassette options.

Dual Process Ready: Underfill + Flux Spraying

Optional spray valve module extends capability to handle flux

coating or pre-soldering adhesion processes.

Precise Wafer Temperature Control

Advanced vacuum chuck table with uniform heating and real-time

feedback ensures stable material flow and void-free filling.

Ultra-Fine Dot Accuracy

X/Y positioning accuracy within ±10μm and Z-axis repeatability of

±5μm deliver consistent results for RDL First structures.

Typical Applications

✔ RDL First Fan-Out WLP

✔ CoWoS (Chip-on-Wafer-on-Substrate)

✔ FoPoP (Fan-Out Package-on-Package)

✔ Wafer-Level Underfill

✔ Wafer-Level Flux Spraying

✔ Semiconductor Flip Chip Packaging

✔ Redistribution Layer Adhesive Coating

Technical Specifications

Cleanliness Level | Cleanliness of working area | Class 100 (Class 1000 workshop ); Class 10 (Class 100 workshop) |

Application Range | Wafer Configuration | φ200±0.5mm/φ300±0.5mm (Standard version supports 12-inch only) |

Wafer Thickness | 300~25500 μm |

Max. Acceptable Wafer Warp | 5mm (subject to Finger model selection) |

Max. Wafer Weight | 600g (subject to Finger model selection) |

Supported Wafer-box Type | 8-inch Open Cassette/ 12-inch Foup (Standard version supports

12-inch only) |

Jetting System | Transmission System | X/Y: Linear motor Z: Servo motor&Screw module |

Repeatability (3sigma) | X/Y:±3 μ m Z:±5 μ m |

Positioning Accuracy (3sigma) | X/Y:±10 μ m |

Max. Speed | X/Y:1000mm/s Z: 500mm/s |

Max. Acceleration | X/Y:1g Z: 0.5g |

Visual System | Pixel | 130W |

Identify Accuracy | ±1pixel |

Identify Range | 10*12mm |

Light Resource | Red, Green, White combined light + extra red illumination |

Weighing Calibration System | Weighing Accuracy | 0.01mg |

Chuck Table | Vacuum Suction Planeness Deviation | ≤30μ m |

Heating Temperature Deviation | ±1.5℃ |

Lifting height repeatability | ±10μ m |

Vacuum Suction Pressure | -85~-70KPa (Settable) |

General Condition | Footprint W× D × H | 3075*2200*2200mm (Display screen unfold) |

Weight | 2900kg |

Power | 16.5KW |

Operation Environment Temperature | 23℃±3℃ |

Operation Environment Humidity | 30-70% |

FAQ

Q1: What unique wafer-level applications does the GS600SW target?

A: It’s engineered for RDL First Fan-Out WLP, CoWoS, and FoPoP

processes where fine underfill control and flux spraying are both

required.

Q2: How does it handle wafer size and warp?

A: It supports standard 8-inch and 12-inch wafers with thicknesses

up to 25,500μm and warp tolerance up to 5mm, with flexible wafer

box compatibility.

Q3: Can it be integrated into fully automated lines?

A: Absolutely. It can work with Mingseal’s PC101EFEM for full auto

wafer handling, pre-alignment, and AMHS robot docking.

Q4: Why choose Mingseal for wafer-level dispensing?

A: With years of experience in semiconductor underfill and fluid

dispensing, Mingseal delivers reliable equipment that integrates

precision mechanics, stable control, and cleanroom

compliance—helping factories reach next-level yield and cost

efficiency.

Conclusion

Mingseal is a trusted supplier of inline and wafer-level dispensing

solutions for global semiconductor and advanced packaging

manufacturers. From underfill to flux coating, our modular systems,

intelligent control, and stable design help our partners deliver

defect-free products for 5G, high-performance computing, and AI

chip markets.